Robotic Tactile Sensing with Capacitive Sensors

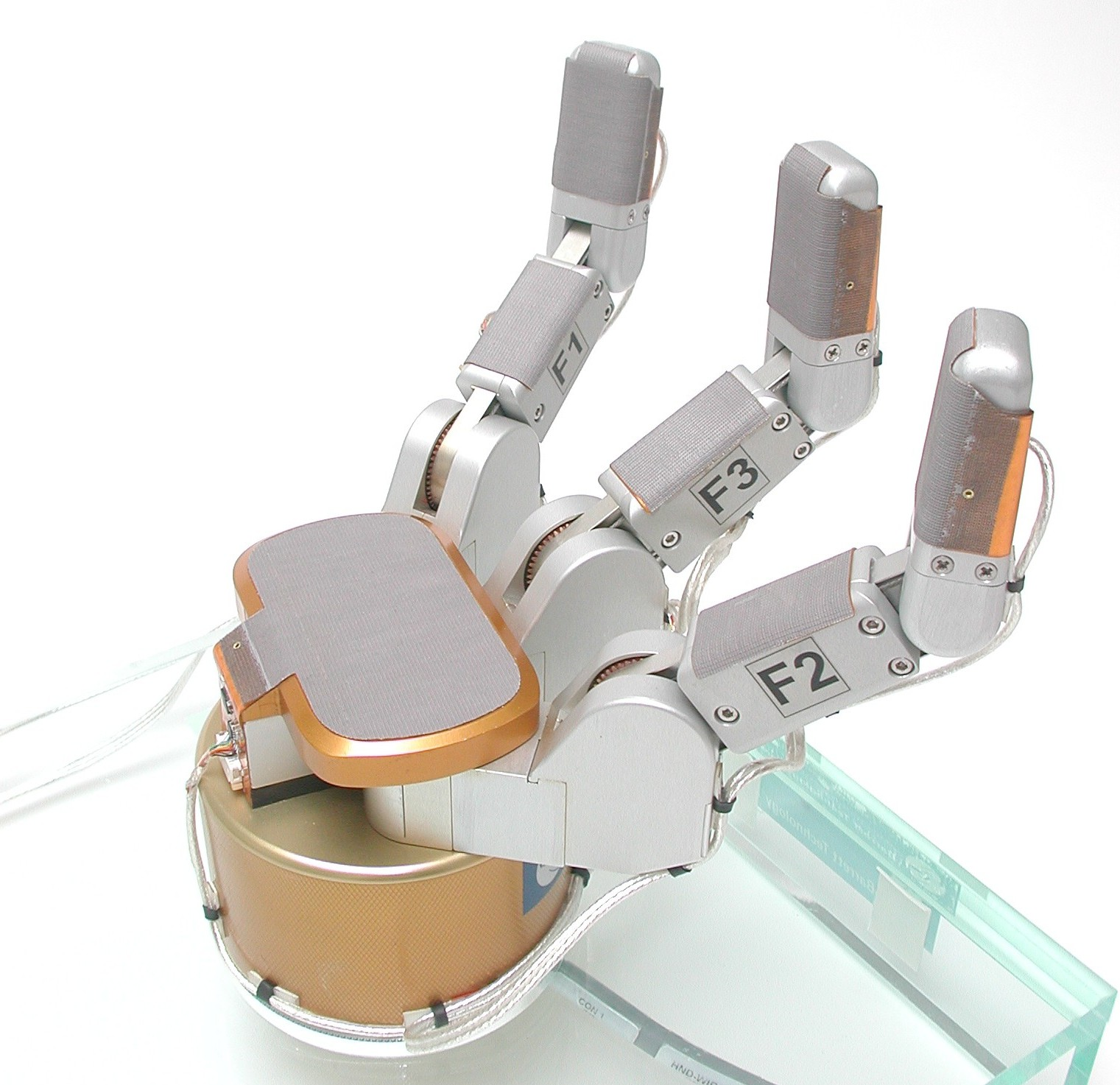

BarrettHand with integrated PPS tactile sensor arrays

Case Study 1: RoboTouch Technology - Giving Robots the sense of touch

RoboTouch sensor technology is an advanced capacitive tactile sensing system designed to provide robots with a sense of touch. Originally developed in 1990s, this technology has undergone extensive refinement to enhance its sensor design and digital interfaces.

The core of RoboTouch technology lies in its capacitive sensing mechanism, which enables robots to detect and measure physical contact and pressure with high precision. This capability is essential for various applications, such as industrial automation, consumer robotics, and humanoid robots. By integrating RoboTouch sensors, robotic grippers can perform delicate and complex tasks that require fine tactile feedback, similar to human touch.

The RoboTouch patented capacitive tactile sensing technology is the highest performance embedded tactile sensing technology for giving industrial and consumer robotic grippers or Humanoid robots the “sense of touch”, improving their interaction with the environment and enabling more sophisticated and precise operations.

Insides into RoboTouch

The RoboTouch technology is based on Digitacts sensor technology that features embedded digital output ideal for OEM integration into the gripper. The sensors consist of multiple sensing pads, each typically with 12-24 sensing elements, which can be placed on any location of choosing in the gripper. Data from sensors are transferred to grippers via I²C or SPI digital interfaces, enabling you to easily integrate the sensors into your device and grippers.

Waseda University in Tokyo and its updated humanoid robot, named Twendy-One

Case Study 2: Twendy-One robot capable of complex tasks

The Twendy-One robot, developed by Waseda University, features advanced tactile sensing capabilities, which are crucial for its interaction with the environment and safe human-robot interaction. These capabilities are enhanced by using tactile sensors provided by PPS.

Twendy-One incorporates a distributed array of these tactile sensors, particularly in its hands, which include 241 sensors each. Additionally, it features soft skin and six-axis force/torque sensors in the fingertips, making it capable of complex tasks such as in-hand manipulation and tactile object recognition. This combination of tactile and force sensors allows the robot to perform tasks safely and effectively, leveraging the tactile feedback for improved control and learning (IAS - TU Darmstadt)

These integrations illustrate the synergy between advanced robotic systems like Twendy-One and cutting-edge tactile sensor technologies like ours, showcasing how we can work together to enhance robotic capabilities and human-robot interaction.

The Willow Garage PR2 Gripper sensor in action

Case Study 3: Willow Garage PR2, the Human-Inspired Robot

The PR2 robot from Willow Garage incorporates our tactile sensing technology to enhance its grasping capabilities. The PPS capacitive tactile sensor arrays are embedded in the gripper's fingertips, enabling the robot to perform actions such as gently picking up and setting down unknown objects by mimicking human sensory channels.

The grasp controller for the PR2 includes six discrete states: Close, Load, Lift and Hold, Replace, Unload, and Open. During these states, the robot processes real-time data from the fingertip pressure arrays and an accelerometer to generate tactile signals similar to human SA-I, FA-I, and FA-II channels. These signals help the robot determine the appropriate grasping force, detect slippage, and decide when to release an object.

This approach is demonstrated on the PR2 robot, showing its ability to handle a variety of real-world objects with precision and care. The tactile feedback allows the robot to adapt its grasp dynamically, providing safer and more effective interaction with its environment.(Blog | Robotiq)

Key Benefits from partnering with us:

The ability to give your robot the “sense of touch”

Providing your robot with the ability to manipulate delicate objects

Optimizing your grippers for low-power operation by minimizing grasping force

Collecting data using the most sensitive and repeatable tactile sensors for robotic applications

The great flexibility of PPS customized sensor design patterns, which can be molded to fit almost any gripper shape while keeping data quality intact.

Working with “The Company to go to” for embedding tactile sensors into robotic grippers.

This technology paves the way for intelligent robots systems that can perform complex manipulation tasks with unprecedented dexterity and sensitivity.

Integrating our sensors into your products...

It will be our pleasure to partner with it to embed our tactile sensor technology into your products, including robotic hand components, through development and licensing/manufacturing services. Our sensors can be customized to fit various design patterns, accommodating different shapes of robotic hands and enhancing their ability to perform a wide range of grasps. Additionally, our technology is adept at measuring the pressure applied by a robotic hand during manipulation tasks, ensuring precise control and interaction with objects and surfaces.

DEVELOPMENT OF TOUCH SENSOR INTEGRATION

We will integrate our sensor solutions into your prototypes.

We will also consult on sensor design, integration, and testing. Additionally, PPS consults on the integration of such sensors, including their use as a limit switch, to ensure optimal functionality and performance in various applications.

Manufacture and supply logistics of prototypes per customer requirements.

COMMERCIAL PRODUCTION

PPS can either license its OEM solutions directly to you.

Or we utilize our strategic manufacturing partners to produce our sensors.

STUDIES & EXAMPLES

RESEARCH ARTICLE - Soft Robotic Glove Modulating Joint Torque Through Novel Passive Extensor Mechanisms - IEEE Robotics & Automation - February 2024

RESEARCH ARTICLE - Modelling of Modular Soft Robots: From a Single to Multiple Building Blocks - Elsevier - January 2024

RESEARCH ARTICLE - Skin-Inspired Triple Tactile Sensors Integrated on Robotic Fingers for Bimanual Manipulation in Human-Cyber-Physical Systems - IEEE - October 2023

RESEARCH ARTICLE - Visual 3D Perception for Interactive Robotic Tactile Data Acquisition - MERL - August 2021

RESEARCH ARTICLE -Tactile Model O: Fabrication and testing of a 3D-printed, three-fingered tactile robot hand - Published 2020

RESEARCH ARTICLE - Pressure Sensor: State of the Art, Design, and Application for Robotic Hand - Hindawi - Published 2015

RESEARCH ARTICLE - Control Framework for Dexterous Manipulation Using Dynamic Visual Servoing and Tactile Sensors’ Feedback - MDPI - Published 2014

RESEARCH ARTICLE - From Robot to Human Grasping Simulation - ResearchGate - Published May 2013

RESEARCH ARTICLE - Human-Inspired Robotic Grasp Control With Tactile Sensing - IEEE Transactions - Published June 2011

FAQ

Why is tactile sensing important in robotics?

Willow Garage - PR2 Fine Motor Skills

Tactile sensing is crucial in robotics for several reasons:

Precision Handling: Tactile sensors allow robots to handle objects with greater precision and care, preventing damage to delicate items and ensuring secure grasping of various objects.

Enhanced Interaction: With a sense of touch, robots can interact more effectively with their environment, performing tasks that require fine motor skills and adaptability.

Safety: Tactile feedback helps robots detect and respond to unexpected physical contact, enhancing safety for both the robot and its human co-workers.

Improved Functionality: Tactile sensing enables robots to perform complex tasks such as assembling delicate components, sorting objects by texture, and even performing medical procedures with a high degree of accuracy.

Adaptability: Robots equipped with tactile sensors can better adapt to different tasks and environments by learning from tactile experiences, improving their performance over time through machine learning.

In summary, tactile sensing is essential for advancing robotic capabilities, making them more versatile, safe, and efficient in a wide range of applications.

What is the application of tactile or force sensors in robotics?

Tactile and force sensors have several critical applications in robotics:

Gripping and Manipulation: Force sensors enable robots to grip and manipulate objects with the right amount of pressure, preventing damage to delicate items and ensuring a secure hold.

Assembly and Manufacturing: In automated assembly lines, force sensors help robots apply precise amounts of force when fitting parts together, ensuring proper assembly and reducing the risk of defects.

Collision Detection and Safety: Force sensors detect unexpected forces or impacts, allowing robots to stop or adjust their movements to prevent collisions and enhance safety for both the robot and nearby humans.

Tactile Feedback: Similar to a sense of touch, force sensors provide tactile feedback, enabling robots to perform delicate tasks that require sensitivity, such as medical procedures or handling fragile objects.

Balancing and Stability: In mobile robots and humanoids, force sensors help maintain balance and stability by adjusting movements in response to changes in force or pressure on different parts of the robot.

Automated Testing: Force sensors are used in quality control to measure the force required to operate products, ensuring they meet specific standards and function correctly.

Overall, force sensors are vital for enhancing the precision, safety, and versatility of robots in various industrial, commercial, and medical applications.